Alliages de Substitution

pour les Productions Electroniques:

Alliages et température de fusion : (Lingots, barres,

baguettes, grenailles, Préformes fils)

Crèmes à braser (pâtes & encres)

LEAD FREE SOLDERS IN ELECTRONICS

• Greater Thermal Stress of Components

• Use of Temperature Sensitive Components and

LEAD FREE

ALTERNATIVE SOLDER ALLOYS

DISSOLUTION

KINETICS OF COPPER

THE EFFECT

OF ISOTHERMAL AGING

Integrity of Solder Joints

from Lead-free Solder Paste

• Greater Thermal Stress of Components

LEAD FREE

ALTERNATIVE SOLDER ALLOYS

96.2Sn/2.5Ag/0.8Cu/0.5Sb (known as Castin) 217-220 °C

90Sn/2.0Ag/7.5Bi/0.5Cu (138) 198-212°C

DISSOLUTION

KINETICS OF COPPER

THE EFFECT

OF ISOTHERMAL AGING

2. Alternative

materials and solder

3. Oxidation

tendency of different

5. Low-melting

binary and ternary

7. Alternative

surface metallizations

Alliages

de Substitution pour les Productions Electroniques:

Alliages et température de fusion : (Lingots, barres, baguettes, grenailles, Préformes fils)

|

Ref. |

composition |

Liquidu |

Solidus |

densté |

|

§ S 100 |

Sn100 |

233 |

E |

7,80 |

|

§ |

Sn90 |

Ag10 |

300 |

227 |

7,32 |

|

§ SA 2.5 |

Sn97,5 |

Ag2,5 |

226 |

221 |

7,34 |

|

§ SA 3 |

Sn97 |

Ag3 |

232 |

E |

7,28 |

|

§ SA 3.5 |

Sn96,5 |

Ag3,5 |

221 |

E |

7,36 |

|

§

SA 5 |

Sn95 |

Ag5 |

240 |

232 |

7,25 |

|

§

SA 5 |

Sn95 |

Ag5 |

222 |

183 |

7,42 |

|

§ SB 40 |

Sn60 |

Bi40 |

170 |

138 |

8,12 |

|

§ SB 5 |

Sn95 |

Sb5 |

248 |

179 |

8,43 |

|

§ SC 0,7 |

Sn99,3 |

Cu0,7 |

227 |

E |

|

|

§ SC 3 |

Sn97 |

Cu3 |

320 |

227 |

|

|

§ SI 42 |

Sn58 |

In42 |

145 |

118 |

7,30 |

|

§ SI 48 |

Sn52 |

In48 |

131 |

118 |

7,30 |

|

§ SS 2 |

Sn98 |

Sb2 |

240 |

221 |

7,39 |

|

§ SS 3 |

Sn97 |

Sb3 |

240 |

235 |

7,28 |

|

§ SZ 9 |

Sn91 |

Zn9 |

199 |

E |

7,27 |

2°) Alliages tertiaires:

|

§

SAB |

Sn |

Ag |

Bi |

|

|

|

|

§

SAC 305 |

Sn96,5 |

Ag3,0 |

Cu0,5 |

217 |

218 |

7,39 |

|

|

Sn95,75 |

Ag3.5 |

Cu0,75 |

217 |

|

7.38 |

|

§ SAC 385 |

Sn95,7 |

Ag 3,8 |

Cu0,5 |

|

|

|

|

§ SAC 387 |

Sn95.5 |

Ag3.8 |

Cu0.7 |

217 |

E |

|

|

§ SAC 408 |

Sn95,2 |

Ag4 |

Cu0,8 |

|

|

|

|

§ SAS 25.10 |

Sn65 |

Ag25 |

Sb10 |

238 |

232 |

7,26 |

2°) Alliages quaternaires:

|

§ SABC |

Sn |

Ag |

Bi |

Cu |

|

|

|

|

§ SAC 0307 Co |

Sn98,07 |

Ag0,3 |

Cu0,7 |

Co 0,03 |

217 |

227 |

7,32 |

Ces

changements peuvent imposer des modifications importantes au niveau

des process, des équipements, et des composants.

En contrepartie, les

alliages "Sans Plomb" présentent une meilleure résistance

au fluage et des caractéristiques de tenue mécanique plus élevées

que l'alliage Sn63Pb37.

|

Désignation de l'alliage |

Zone de fusion |

Poids. |

|

|||

|

Alliages

sans plomb RoHS |

Solide |

Liquide |

spéc |

Domaines

d'utilisation |

|

|

|

|

Sn 97 Ag2 Cu Sb |

216 °C |

221 °C |

7.3 |

Soudure fine sur C.I. - Soudage de composants pour constructions radio, télévision, retouches, trous métallisés. Soudure pour professionnel, câblage conventionnel. - Appareil de mesure. - Circuits imprimés cuivre nu. - Améliore la résistance mécanique. Soudage sur circuits dorés, céramiques argentées et toutes bases argentées. - Soudure utilisée pour des ensembles travaillant à des températures élevées (lampes, moteurs,…) Soudure sur céramique argentée, circuits imprimés, basse température, points juxtaposés. Soudure spéciale pour grande résistance mécanique. - Soudures sans plomb pour contact alimentaire. |

|

|

|

Sn 96 Ag |

221 °C |

eutectique |

7.3 |

||

|

|

Sn 100 |

232 °C |

Fusion |

7.3 |

||

|

|

Sn 97 Cu Sn 99 Cu |

227 °C 227 °C |

320 °C eutectique |

7.3 7.3 |

||

Crèmes à braser (pâtes & encres)

Tableau

des Crèmes

Le monde

du "sans plomb" regorge d’acronymes, d’abréviations et de

termes qui ne vous sont peut-être pas familiers. Grâce à cette page,

nous ferons de notre mieux pour lever le voile sur vos doutes et vos

interrogations compte-tenu de l’évolution de la législation RoHS.

|

Acronyme |

Définition |

Signification |

|

ASO |

Ag / Sn / O2 |

Oxyde d'Etain/d'Argent |

|

SAC |

Sn / Ag / Cu |

Alliage Etain Argent Cuivre |

|

SAB |

Sn / Ag / Bi |

Alliage Etain Argent Bismuth |

|

SABC |

Sn / Ag / Bi / Cu |

Alliage Etain Argent Bismuth Cuivre |

|

SAC408 |

Sn / Ag 4% / 0,8% Cu |

Alliage mixte |

|

SAC385 |

Sn / Ag 3,8% / 0,5% Cu |

Alliage mixte |

|

SAC305 |

Sn / Ag 3,0% / 0,5% Cu |

Alliage mixte |

|

NiAu |

Nickel / Or |

|

|

Pb |

Plomb |

Symbole chimique |

|

Cd |

Cadmium |

Symbole chimique |

|

Hg |

Mercure |

Symbole chimique |

|

Sn |

Etain |

Symbole chimique |

|

Ag |

Argent |

Symbole chimique |

|

Bi |

Bismuth |

Symbole chimique |

|

Cr (VI) |

Chrome hexavalent

|

|

|

PBB |

Biphényles polybromés

|

Ignifugeants |

|

PBDE |

Diphényléthers polybromés

|

Ignifugeants |

|

BGA |

Boîtier à matrice de billes |

|

|

CSP |

Boîtier-puce |

|

|

CRT |

Tube cathodique |

|

|

DTI |

Ministère britannique du Commerce et de l’Industrie

|

Ministère clé chargé de promouvoir la mise en

conformité avec la Directive RoHS

|

|

DEFRA |

Ministère britannique de l’Environnement, de

l’Alimentation et des Affaires rurales |

Ministère de l’environnement |

|

CE |

Commission européenne |

|

|

ED-XRF |

Analyse par fluorescence X à dispersion d'énergie

|

|

|

ELV |

Véhicules hors d'usage |

Directive de l'Union européenne |

|

ESH |

Environnement, Sécurité et Hygiène |

|

|

HASL |

Nivellement de la soudure à l'air chaud |

|

|

IT |

Technologie de l'information |

|

|

LFS |

Soudure sans plomb |

|

|

MCV |

Valeur de concentration maximale |

|

|

MLCC |

Condensateurs céramiques multicouches |

|

|

m.pt. |

Point de fusion |

|

|

MSL |

Niveau de sensibilité à l'humidité |

|

|

OEM |

Equipementier |

|

|

PCB |

Carte imprimée |

|

|

PVC |

Chlorure de polyvinyle |

|

|

QA |

Assurance Qualité |

|

|

RoHS |

Restriction de l'utilisation de certaines substances

dangereuses |

Directive de l'Union européenne |

|

SME |

Petites et moyennes entreprises |

|

|

TAC |

Comité d'adaptation technique |

Comité technique de l'Union européenne |

|

TCF |

Dossier de conformité technique |

|

|

VOC |

Composé organique volatil |

|

|

WD-XRF |

Analyse par fluorescence X à dispersion de longueur

d'onde |

|

|

DEEE |

Déchets d'équipement électrique et électronique

|

Directive de l'Union européenne |

LEAD FREE SOLDERS IN ELECTRONICS

Angela Grusd

Heraeus Inc.

West

Lead-bearing solders are used extensively in the electronics

industry. In recent years, efforts to develop alternatives to lead-based

solders have increased significantly. As researchers began to focus

on Pb-free solders they recognised their

potential in high temperature applications such as automotive where

Sn/Pb solders do not meet the demanding

requirements. In particular, the Sn-Ag-X lead free solders offer superior creep resistance

at room temperature and 100°C as

compared to Sn-40Pb. Results of this work will be presented as well

as factors to consider when developing

and implementing lead free alloys such as manufacturability,

availability, and cost. One of the most promising replacement alloys

is Sn/4Ag/0.5Cu. This alloy will be discussed in detail.

Lead free solders are currently in production in some

facilities and some of the “green” companies have proposed timelines

for their implementation in the next year. The development of lead

free lternatives was initially driven by impending

Automobile Industries Association. This called for a

50% voluntary reduction of lead in vehicles (excluding batteries)

by 2001 and to one-third by 2003. Several major Japanese Consumer

Electronic Manufacturers have publicly announced accelerated plans

to eliminate lead solder completely by 2001. Lead free alternatives

are being considered for several reasons:

• Health Concerns

It is widely known that lead is related to certain health

risks. If lead particles are inhaled or ingested, they accumulate

in the human body causing damage to the blood and central nervous

systems. Lead poisoning can be detected by blood analysis and the

limits are defined by national governments.

The standard upper value of untainted human beings should

not exceed 130 µg/l. The upper blood lead limit of people who are

exposed to lead at work is, according to the

As a result, some industries have already eliminated

lead and have found suitable alternatives, for example plumbing solders,

tinned cans, lead-free gasoline for vehicles, and leadfree

cut crystal glass. The majority of lead consumption is automobile

batteries and ammunition. The lead consumption of the electronics

industry is relatively small and, according to different sources,

lies between 0.5 - 7%.

When choosing alternative metals, consideration must

also be given to their health risks as well. Recent studies in the

the toxicology of lead and some alternative metals:[1]

• Cd is extremely toxic and

should not be used (high risk). Many companies such as Ford Motor

Company have banned Cd-containing materials.

• Pb was also identified as

highly toxic (high risk - it is considered harmful to the reproductive

system).

• Sb is very toxic and should

not be considered a major alloying element (medium risk - in

• Ag and Cu are used in lead-free alloys in small concentrations

- in

• Sn and Zn are essential elements

in the human diet, yet may be toxic if exposures are sufficiently

high (low risk).

• Bi is a relatively benign metal with a history of medicinal

uses (low risk).

• Greater Thermal Stress of Components

In the automotive industry, more and more circuits are being

placed in the engine compartment in order to reduce the

quantity of cables and, therefore, reduce cost. These under

the hood conditions often see temperatures in excess of

150°C. A leading automobile manufacturer has even

measured temperatures as high as 170°C on a hybrid circuit.

The high thermal stresses imposed on the solder joints at

these temperatures has led automotive manufacturers to

research Pb-free alternatives with high thermal

fatigue

resistance, because they observed that Sn-37Pb has poor

thermal fatigue properties even at 125°C. Higher

temperatures dramatically reduce the strength of the

solder joint during thermal cycling, due to greater plastic

deformation of the solder as well as diffusion,

recrystallization and grain growth

inside the solder.

For conventional alloys such as Sn62/Pb36/Ag2 (melting

point 179°C) and Sn63/Pb37 (melting point 183°C),

there is a major concern for the mechanical and

microstructural stability and,

therefore, the reliability of

the solder joint at an operating temperature of 150°C,

because it is approaching the melting point of the alloy.

• Use of Temperature Sensitive Components

and

Some industries have driven down costs by replacing

higher cost plastic components with less expensive

plastic ones. These components, however, cannot

withstand the standard reflow temperatures of

210-

230°C. Therefore low melting temperature solder alloys

are used in this case. This is especially apparent with

consumer electronics, as the operation temperatures are

from 0°C to +60°C. This lower temperature range

corresponds to much less thermal stress on the solder

joints as compared to those temperatures found in underthe-

hood applications which typically reach 150°C or

greater. An example of a solder for these lower

temperature applications is Sn/Bi eutectic.

LEAD FREE ALTERNATIVE SOLDER ALLOYS

1. Sn/Ag (96.5Sn/3.5Ag:221°C)

This alloy exhibits adequate wetting behavior

and

strength and is used in electronics as well as plumbing.

Several sources have also reported good thermal fatigue

properties as compared to Sn/Pb. Thermal fatigue

damage in solders is accelerated at elevated temperatures.

In the Sn/Pb system, the relatively high solid

solubilities

of Pb in Sn and vice

versa, especially at elevated

temperatures, lead to microstructural instability

due to

coarsening mechanisms. These regions of

inhomogeneous microstructural coarsening are

known to

be crack initiation sites. It is well-documented that these

types of microstructures in Sn/Pb alloys fail

by the

formation of a coarsened band in which a fatigue crack

grows. By comparison, the Sn/Ag system, has limited

solid solubility of Ag in Sn, making it more

resistant to

coarsening. As a result, Sn/3.5Ag eutectic forms a more

stable, uniform microstructure that is more reliable.

Although the Sn/3.5Ag alloy itself exhibits good

microstructural stability, when

soldered to copper base

metal, the combination of a higher Sn content

(96.5Sn

compared to 63Sn) and higher reflow temperature

environments accelerate the diffusion rates for copper base

metal in Sn. As its corresponding composition

is reached, the

brittle Cu6Sn5 intermetallic compound is nucleated

and begins

to grow. To slow the diffusion rate and thereby decrease the

growth kinetics, alternative surface finishes such as

immersion gold (Au over Ni over Cu) may be used. The 2 µm

Ni in the immersion gold coating serves as an effective

diffusion barrier, limiting the Cu from diffusing into the

solder and forming the brittle Cu6Sn5 intermetallic compound.

Other surface finishes such as immersion silver (Ag over Cu)

and immersion palladium (Pd over Cu) do not contain a Ni

barrier layer. Their effect on the growth kinetics of the

intermetallic compound layers

is under investigation.

1) 95.5Sn/4.0Ag/0.5Cu

217-219°C

2) 95.5Sn/3.8Ag/0.7Cu

217-219°C

3) 95.0Sn/4.0Ag/1.0Cu

217-219°C

4) 93.6Sn/4.7Ag/1.7Cu 216-218°C

Because the mechanical stability of the joint is degraded when

the melting point is approached, elevated temperature cycling

produces more damage for Sn/Pb solder (m.p. 183°C) as

compared to higher melting point solders. The melting

temperatures of Sn/Ag/Cu solders make them ideal

in high

operating temperatures up to 175°C. As for wetting,

Sn/Ag/Cu solders do not wet

Cu as well as Sn/Pb using

commercial fluxes. However, good fillet formation can be

easily achieved provided the fluxes are suitable for higher

temperature use. Soldering in nitrogen atmosphere also

improves wettability using no-clean fluxes. The

copper

dissolution test provides a relative measurement of the

solder’s tendency to dissolve Cu from the base metal and

form the Cu6Sn5 intermetallic compound. For

alloys 1-3, the

rate of copper dissolution is slower than the Sn/Ag

alloy yet

faster than the Sn/Pb eutectic. For alloy 4,

the high level of

Cu in the alloy prevented the dissolution of the copper wire

(See Dissolution section).

3. Sn/Cu (99.3Sn/0.7Cu:227 °C)

This alloy might be also suitable for high temperature

applications required by the automotive industry. It is a

candidate especially for companies looking for lead and silver

free alloys. Preliminary testing conducted on this alloy has

shown a significant improvement in creep/fatigue data over

standard Sn-Pb alloys.

4. Sn/Ag/Cu/Sb (96.2Sn/2.5Ag/0.8Cu/0.5Sb

(known as Castin):217-220 °C)

This alloy has similar mechanical properties to the Sn/Ag/Cu

alloy.

5. Sn/Ag/Bi

(91.8Sn/3.4Ag/4.8Bi:200-216°C)

In general, bismuth is added to Sn/Ag/X solder

alloys in

order to depress the melting point. Another benefit of Bi

addition is greater joint strength as indicated by ring and plug

testing. This particular alloy was developed by Sandia

National Labs. Sandia’s internal studies have

found no

electrical failures on surface mount devices following

10,000 thermal cycles using 68 I/O PLCCs, 24

I/O

SOICs, and 1206 chip capacitors

on standard FR-4

PCBs. The boards were cycled 0 to 100°C at a ramp rate

of 10°C/ minute. No cracks or deformation were observed

on boards cross-sectioned after 5000 thermal cycles.

Cross-sectional data on 10,000 cycles is being collected.

These results are in good agreement with data collected

by the

(NCMS) Lead Free Solder Project, which reported very

good thermal fatigue resistance on OSP printed circuit

boards (Organic Solderability Preservative that

protects

copper pads and through-holes). The NCMS High

Temperature Fatigue Resistance Project is currently

evaluating this solder at temperatures up to 160 and

175°C. In combination with Pb from the PCB or

component metallisation, a Sn/Bi/Pb

ternary compound

is formed with a melting point of only 96°C. As the trend

toward eliminating lead continues, this alloy may become

more attractive.

6. Sn/Ag/Bi/Cu (90Sn/2.0Ag/7.5Bi/0.5Cu

(138):198-212°C)

Although the addition of Bi to the Sn/Ag/X system

imparts greater strength and improved wetting, too much

bismuth (greater than 5%) leads to the presence of a

small DSC peak near 138°C, corresponding to the binary

Sn/Bi eutectic at 138°C or the

ternary Sn/Ag/Bi eutectic

at 136.5°C. For this alloy with 7.5 weight percent Bi, this

corresponds to approximately 1% of the total melting.

This small amount of eutectic melting has an uncertain

effect on joint reliability as the temperature approaches

138°C. This combined with the aforementioned concern

of forming a SnPbBi compound at 96°C, makes this

alloy

an unlikely candidate for a Pb-free solder.

7. Sn/Bi (42Sn/58Bi:138°C)

The low melting point of this alloy makes it suitable for

soldering temperature-sensitive components and

substrates. If these contain Pb, the SnPbBi ternary

eutectic compound may form at 96°C, which in turn

adversely affects the thermal fatigue properties. The

NCMS Lead Free Solder Project recently reported the

results of thermal cycle testing at 0/ 100°C and -55/

+125°C for over 5000 cycles on OSP boards. The result

was that the Sn/Bi outperformed the Sn/Pb at both

temperature excursions. It was thought that the closeness

of 125°C to the binary Sn/Bi eutectic at 138°C

would

cause this alloy to be a poor performer. Two possible

explanations for this unexpected result were presented.

The Sn/Bi alloy may be annealing at 125°C, relaxing

the

stresses produced during thermal cycling. A second

explanation was the alloy may be undergoing

recrystallization.

8. Sn/Sb (95Sn/5Sb:232-240°C)

The 95Sn-5Sb solder is a solid solution of antimony in a tin

matrix. The relatively high melting point of this alloy makes

it suitable for high temperature applications. The antimony

imparts strength and hardness. In comparing the yield

strengths of several solder alloys, the strength of 95Sn/5Sb

was 37.2 N/mm2 and was nearly the same as 96.5Sn/3.5Ag

(37.7 N/mm2 ).[2] The high strength

of this alloy causes the

lowest energy crack path to be at the solder/intermetallic

interface in the case of thinner intermetallics.

As the

intermetallic thickens, the

crack path is through the

intermetallic layer. Formation

of the intermetallic compound

SbSn is possible at these levels

of Sb. This phase has a cubic

structure with a high hardness. The wetting behavior

was

measured on a wetting balance in air using a standard RMA

flux. The wetting force at 2 seconds for 95Sn/5Sb on a Cu

wire is significantly less than Sn/37Pb and Sn/3.5Ag. In

addition to marginal wetting performance, the toxicity of Sb

has also raised concerns. As with bismuth, antimony is also a

by-product in the production of lead.

9. In/Sn (52In/48Sn:118°C)

The melting point of this alloy makes it suitable to low

temperature applications. With regard to indium, it displays

good oxidation resistance, but is susceptible to corrosion in a

humid environment. It is also a very soft metal and has a

tendency to cold weld. In addition, the 52In/48Sn alloy

displays rather poor high temperature fatigue behavior,

due to

its low melting point. The high indium content limits the

widespread use of this alloy due to cost and availability

constraints.

10. Sn/Zn (91Sn/9Zn:199°C)

The presence of zinc in solder alloys leads to oxidation and

corrosion. Samples of bulk alloys that were steam aged for 8

hours exhibited severe corrosion as evidenced by a purplish

color. In powder form, it reacts

rapidly with acids and alkalis

and forms a gas. Zinc-containing solder alloys have been

known to react with the flux medium in as little as a day,

resulting in a paste that is “hard as a rock”. Thus, its

compatibility with fluxes and its storage stability is

questionable. The reflowed solder joints do not

wet as well as

other lead-free alloys. When wave soldered, this alloy tends

to produce excessive dross. Therefore, manufacturability of

this alloy and zinc-bearing alloys in general is a concern.

11. Au/Sn (80Sn/20Au:280°C)

Au/Sn eutectic solder is a very strong, rigid

solder due to the

formation of brittle intermetallic compounds.

Problems of

cracked dies have been seen using Au/Sn eutectic

solders in

die attach applications. It is not known if the cracks occur

from processing or during thermal cycling. The high cost of

this alloy restricts its use in many applications where cost is a

factor.

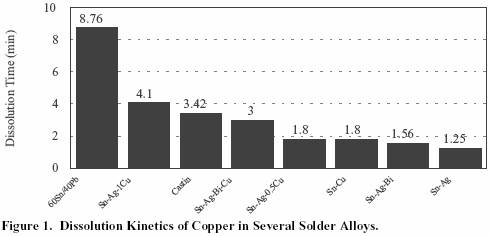

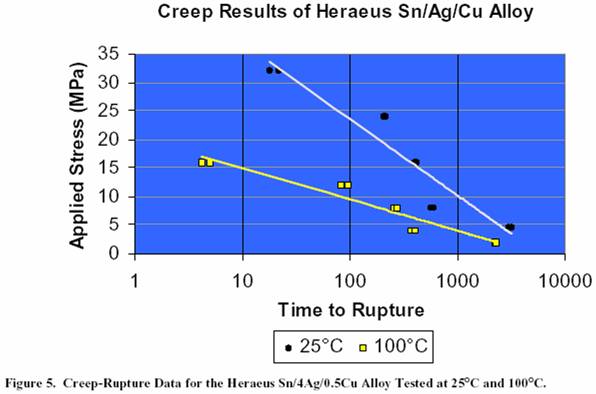

DISSOLUTION KINETICS OF COPPER

In the electronics industry, copper is commonly used as a

basis material for

• conductor traces and solder pads on the PCB

• lead frames of SO, QFP, PLCC, and other

components.

Alloys with a high tin content and a higher melting point

have a greater tendency to dissolve copper. If a larger

quantity of copper is dissolved from the base metal into

the solder material, there is excessive formation of the

Cu6Sn5 intermetallic phase. Solder joint reliability can

be adversely affected by the brittle nature of this

intermetallic compound, in

particular the mechanical

properties of the solder joint, especially under high

impact conditions.[3]

The extent of copper dissolution in various alloys can be

evaluated by means of a simple test. A 50 gram weight

was attached to a 125 µm diameter copper wire. A small

quantity of A611 liquid flux was brushed on the copper

wire. Then the alloy was placed on the tip of a soldering

iron (pre-heated to 280°C), and the soldering iron was

positioned so it made contact with the copper wire. The time

it took to break the copper wire (i.e. until the copper dissolved

in the solder) was measured and recorded as the dissolution

time.

The following alloy compositions were tested:

• 60Sn/40Pb,

• 95Sn/4Ag/1Cu,

• Castin 96.2Sn/2.5Ag/0.5Sb/0.8Cu,

• 95.5Sn/4Ag/0.5Cu,

• 88Sn/3Ag/8.5Bi/0.5Cu,

• 88.42Sn/3.07Ag/8.51Bi,

• 99.3Sn/0.7Cu,

• 96.5Sn/3.5Ag.

60Sn/40Pb had the slowest rate of dissolution of the copper

wire as expected due to its lower Sn content.

For the high tin

solders, the graph shows that the addition of 0.5% copper to

the solder alloy can decrease the dissolution rate dramatically.

In the case of the Sn/Ag/Bi alloy, the effect

of adding 0.5%Cu

was to increase the dissolution time from 1.5 minutes for

Sn/Ag/Bi to 3 minutes for Sn/Ag/Bi/0.5Cu.

8.76

4.1

3.42 3

1.8 1.8 1.56 1.25

60Sn/40Pb

Sn-Ag-1Cu

Castin

Sn-Ag-Bi-Cu

Sn-Ag-0.5Cu

Sn-Cu

Sn-Ag-Bi

Sn-Ag

0

2

4

6

8

10

Dissolution Time (min)

Figure 1. Dissolution Kinetics of Copper in Several Solder Alloys.

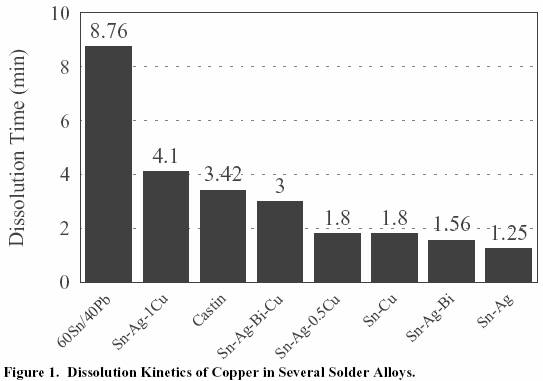

THE EFFECT OF ISOTHERMAL AGING

It is important to study intermetallic growth

formation

because in solder joints with coarsened Cu-Sn

intermetallics, fracture is

brittle and occurs through the

intermetallic layer. An aging

study was performed on

96.5Sn/ 3.5Ag and 95.5Sn/ 4Ag/ 0.5Cu solder alloys on

copper substrates. The intermetallic layer growth

characteristics of the two alloys were compared in order

to determine the effect of copper addition to Sn-Ag

based

alloys.

Two solder pastes were made, 96.5Sn/ 3.5Ag and

95.5Sn/ 4Ag/ 0.5Cu. The pastes were made with -325/

+500 mesh electronic grade (Type 3) powder. A 1000

gram batch of each paste was mixed in a small productionscale

Ross mixer at 89.5% metal loading/ 10.5% flux by

weight. Heraeus V365 no-clean/ halide-free flux

was used.

The test pieces were 2” x 2” copper coupons cut from 0.021

inch thick, commercial grade alloy 110 copper foil. They

were then pressed flat and cleaned in acetone. The solder

paste was screen printed through an 8 mil thick, stainless

steel, laser cut stencil on a DEK 247 printer with all printing

parameters kept constant. Therefore, the solder volume is

presumably constant and was not considered a factor in this

study. Six coupons of each alloy were printed. The printing

characteristics of both pastes were very good.

The test coupons were reflowed at Heraeus in a nitrogen

convection reflow oven using a standard profile

for the

pastes. The test pieces were then placed in a Lindberg/

Blue M air convection oven held at 150°C. The samples

were aged for periods of 2, 4, 11, 20, and 41 days (984

hours). Following aging, each sample was sectioned across 3

joints for metallographic examination. For each sample, the

average thickness of the resulting interfacial compound was

reported.

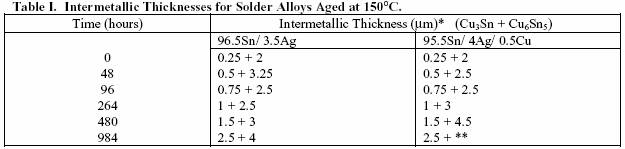

Time (hours) Intermetallic Thickness (µm)* (Cu3Sn + Cu6Sn5)

96.5Sn/ 3.5Ag 95.5Sn/

4Ag/ 0.5Cu

0 0.25 + 2 0.25 +

2

48 0.5 + 3.25 0.5 + 2.5

96 0.75 + 2.5 0.75 + 2.5

264 1 + 2.5 1 + 3

480 1.5 + 3 1.5 + 4.5

984 2.5 + 4 2.5 + **

*The standard deviation for the measurements is on the order of 0.5 µm.

**A nonuniform morphology

of the Cu6Sn5 layer precluded a characteristic thickness measurement.

It is widely known that copper is soluble in molten Sn-

Ag-X solders. The dissolution of copper results in the

formation of å-phase Cu3Sn and ç-phase Cu6Sn5. Due to

the concentration gradient, the Cu-rich Cu3Sn phase

forms adjacent to the copper substrate. Cu3Sn has a more

planar structure. The more Sn-rich Cu6Sn5 phase forms

adjacent to the Sn-based solder and has a scallop-edge

appearance. The reason why Cu6Sn5 has a scallop-edge

appearance may be due to the fact that Cu6Sn5 dissolves

faster along the grain boundary. Between the Cu6Sn5

grains, there are molten solder channels extending all the

way to the Cu3Sn/Cu interface. Since the Cu3Sn

compound layer is so thin, these channels serve as fast

diffusion and dissolution paths of Cu in the solder to feed

the interfacial reaction.[4] This interfacial layer grows

during solid-state aging as the tin and copper diffuse to

the interface and react.

The growth kinetics of the intermetallic compounds

was

found to be similar as expected due to the similar Sn

contents and reflow temperatures of the two alloys.

The

microstructural features of the

Sn-Ag-X alloys are also

similar. The matrix is polygranular Sn with a grain size

in the as-solidified condition of approximately 1 µm.[5]

Five phases can be seen in the SEM micrographs given

in Figures 6 to 17: Sn, Ag3Sn, Cu6Sn5, Cu3Sn, and Cu.

Recent work indicates that similar failure mechanisms are

involved in thermal fatigue in shear and unidirectional creep

in shear. Also, since the temperatures during thermal fatigue

represent high solder homologous temperatures, creep

deformation is involved. Creep deformation is the timedependent

plastic flow of a material under constant load at

elevated temperature. As the homologous temperature (the

ratio of the test temperature to the melting temperature on an

absolute temperature scale) increases, the ease with which

plastic flow occurs also increases. Creep is significant at a

homologous temperature greater than 0.5. Therefore, creep

deformation occurs in solders even at room temperature.

Every high temperature excursion results in a straining of the

solder joint as the constraining materials expand different

amounts. By understanding the mechanisms that lead to

fatigue failures, researchers can use the appropriate

metallurgical strategy to slow down or stop these mechanisms

and thus develop an improved, more fatigue resistant solder

alloy.[6]

The elevated operating temperature and operative strain rates

imply that creep is the major deformation mode during low

cycle fatigue. Also, the observation that solder joint fatigue

failures and creep failures appear the result of similar

metallurgical mechanisms indicates that both techniques can

be used to study the fatigue failure mechanism and relative

solder alloy fatigue resistance. As such, it becomes important

to understand how the solder microstructure accommodates

the applied strain. For the Sn-Ag-X solders,

the strain

accommodation occurs through the tin matrix at individual

Sn-Sn grain boundaries.[5]

Creep testing was performed on samples of the same

dimension and preparation method as that used for

standard tensile testing of solder alloys. All creep testing

was performed at International Tin Research Institute

(ITRI). To generate the creep-rupture data, the solder

alloys were cast into dumbbell-shaped test samples

having 20 mm gauge length and 2 mm diameter. They

were cast at a temperature of 50 degrees above the

liquidus into a heated

steel mold. The mold

was then

water cooled. Samples were then subjected to the

standard aging procedure of 24 hours at 125°C, in

addition to at least 24 hours at room temperature for the

benefit of stabilizing the microstructure as much as

possible.

Samples were held isothermally at both room

temperature and 100°C. A weight was hung from the

sample during the test representing an applied stress, and

the time to rupture was recorded. Samples and test

method conformed to the British Standard BS3500: part

3: 1969 “Method for Creep and Rupture Testing of

Metals.” Time to rupture was determined by measuring

electrical resistance across the sample; after fracture the

resistance became infinite and timing stopped. All

samples were tested in duplicate. Data was collected for

3 different loads (4, 8, and 16 MPa) at both

temperatures.

Results for time to failure at 100, 500, and 1000 hours were

recorded. Loads were applied which were expected to give

lifetimes in the region of those times but extrapolation was

carried out to estimate values for the times required. The

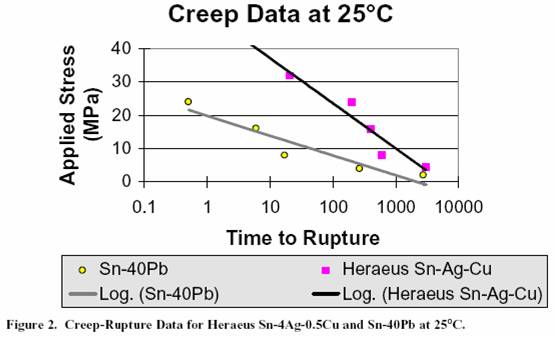

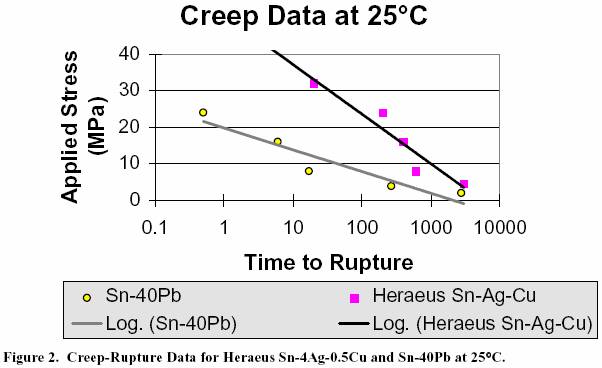

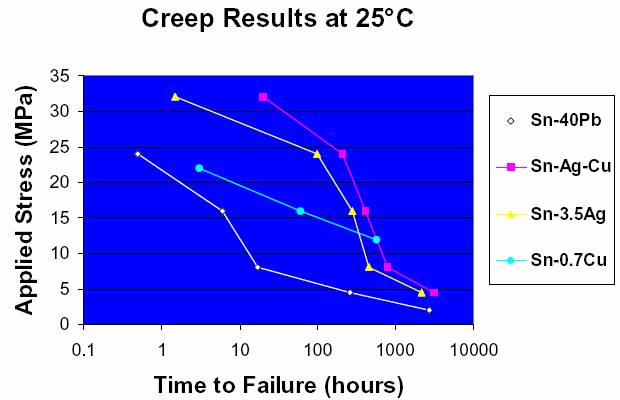

results at 25°C are shown in Figure 2. To interpret the data,

compare the times to rupture for a similar applied stress on

the two alloys. For example, for an applied stress of 4 MPa,

Sn/40Pb failed after 265 hours, whereas the

95.5Sn/4Ag/0.5Cu alloy took 3000 hours for failure to occur.

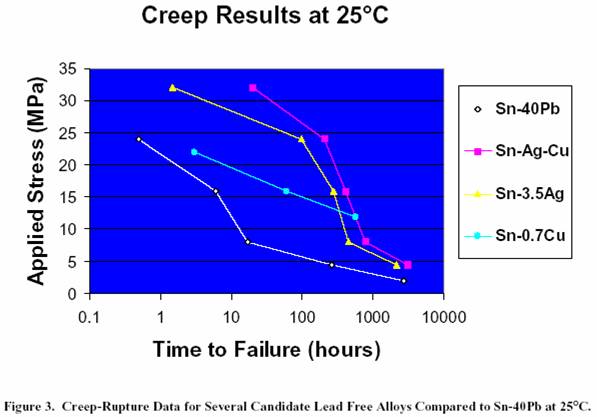

Figure 3 presents the data collected at ITRI for several

candidate lead free alloys compared to Sn/40Pb. The

95.5Sn/4Ag/0.5Cu alloy performs the best at room

temperature compared to Sn/3.5Ag eutectic, Sn/0.7Cu

eutectic, and Sn/40Pb. As expected, the Sn/Ag/Cu

and

Sn/Ag alloys behave similarly

due to their similar

microstructural development.

The graphic representation of

the Sn/Cu data greatly differs from that of the

other three,

perhaps indicative of a different failure mechanism. The

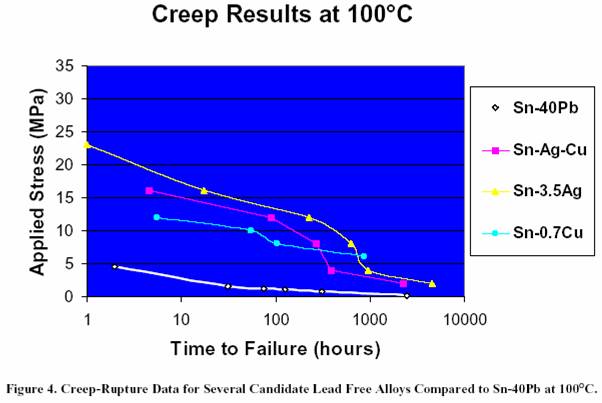

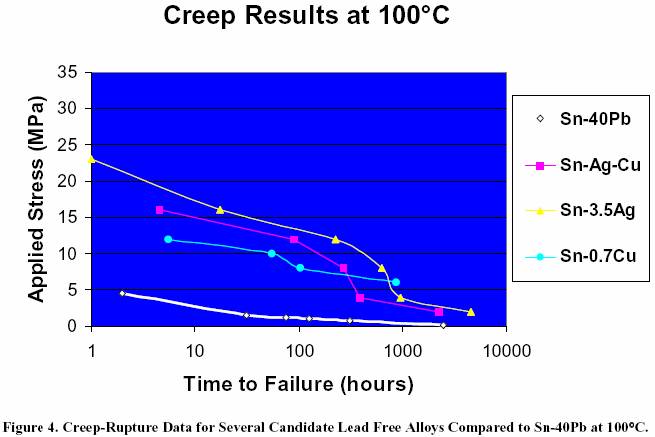

results of creep testing at 100°C are presented in Figure 4. At

100°C, the Sn/Ag and Sn/Ag/Cu

curves appear switched from

the 25°C results with the best performer now being the Sn/Ag

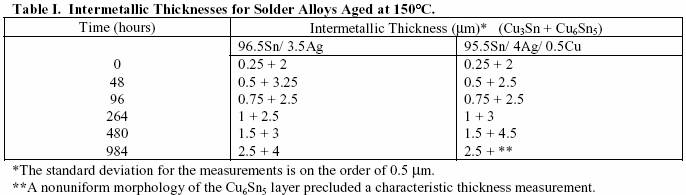

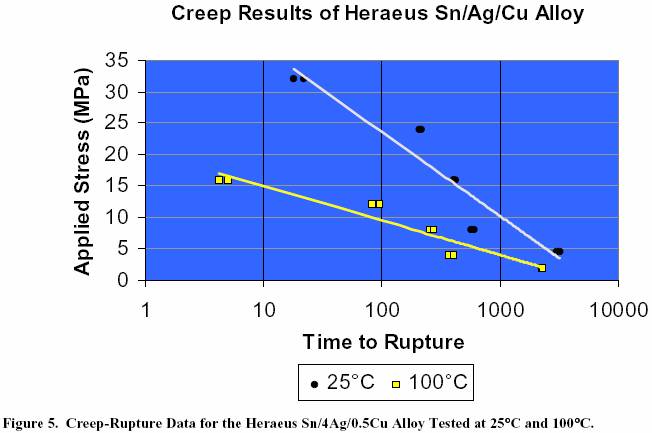

eutectic alloy. Figure 5 shows the creep-rupture data for the

Heraeus Sn/4Ag/0.5Cu

alloy tested at both room temperature

and 100°C. As expected, higher temperatures allow materials

to creep at a faster rate, thereby reducing the time to failure.

Figure 3. Creep-Rupture Data for Several Candidate Lead Free Alloys Compared

to Sn-40Pb at 25°C.

Figure 4. Creep-Rupture Data for Several Candidate Lead Free Alloys Compared

to Sn-40Pb at 100°C.

Figure 5. Creep-Rupture Data for the Heraeus

Sn/4Ag/0.5Cu Alloy Tested at 25°C and 100°C.

Recent work with candidate lead free alloys indicate a

significant improvement in reliability over Sn/Pb.

Figures 2-4 clearly demonstrate a superior creep

resistance over Sn/Pb for all lead free alloys

tested

including Sn/Ag eutectic, Sn/Cu

eutectic, and

Sn/4Ag/0.5Cu at both room temperature and 100°C.

Although the Sn/Cu eutectic outperformed Sn/40Pb,

it

did not perform as well as the Sn-Ag-X alloys.

An aging study of both the 95.5Sn/4Ag/0.5Cu and

96.5Sn/3.5Ag solder alloys was performed in order to

evaluate the growth kinetics of the intermetallic

layers

following extended heat treatment. An understanding of

the microstructural evolution that occurs at

the

solder/copper interface at elevated temperatures is helpful

to understand the failure mechanisms that dominate at

elevated temperatures. Creep occurs when materials

under constant stress, below the tensile stress, slowly

deform and finally fracture. The creep rate is dependent

on alloy composition and microstructure and is strongly

temperature dependent. Because Sn/Ag and Sn/Ag/Cu

have similar microstructures, they behave similarly

during isothermal aging and creep testing.

The author is grateful to acknowledge the support of the

International Tin Research Institute for mechanical

testing of the alloys. The metallographic preparation and

scanning electron microscopy of the samples used to study

aging was performed by F.W. Gayle and L. Smith at the

National

appreciated. Also, thanks to Dr. M.R. Notis of

Lehigh

University and A. Z. Miric of Heraeus

useful discussions.

1.

Solder Project Final Report, August 1997.

2. P.T. Vianco, K.L. Erickson,

and P.L. Hopkins, “Solid

State Intermetallic Compound Growth Between Copper

and High Temperature, Tin-Rich Solders-Part I:

Experimental Analysis,” Sandia National Labs

(Contract

Number DE-AC04-94AL85000), 1994.

3. G. Humpston and D.M. Jacobson,

Principles of Soldering

and Brazing, ASM International,

1993.

4. H.K. Kim and K.N. Tu, “Kinetic

Analysis of the

Soldering Reaction Between Eutectic SnPb Alloy

and Cu

Accompanied by Ripening,” Physical Review B, Vol. 53,

No. 23,

5. D.R. Frear, “The Mechanical

Behavior of Interconnect

Materials for Electronic Packaging,” J.Metals,

(May

1996), pp. 49-53.

6. J.W. Morris, Jr. and D.

Tribula, “Creep in Shear of

Experimental Solder Joints,” Journal of Electronic

Packaging, June 1990, Vol.

112, pp. 87-93.

Integrity of Solder Joints from Lead-free Solder Paste

Angela Grusd

Heraeus Inc.

West Conshohocken, PA

This past year the Lead Free

Movement has taken center stage in the electronics

assembly industry. In

December 1997, the Japan Environmental

Agency proposed legislation on the disposal of lead scrap. Leadcontaining

scrap, such as electronics,

must be disposed of in sealed landfill sites to prevent the leaching

of lead.

A second Japanese proposal

was initiated by the Ministry of International Trade and Industry

(MITI) and the

(excluding batteries) by 2001

and a 66.67% reduction by 2003. The committee of JEIDA (Japan Electronic

Industry Development Association)

and the lead-free soldering committee of JIEP (Japan Institute of

Electronics

Packaging) outlined the lead-free

road map for soldering on

major Japanese Consumer Electronic

Manufacturers initiated their own road map and publicly announced

accelerated plans to eliminate

lead solder completely by 2001.

Matsushita (Panasonic):

It is reported that by 2001,

all lead will be eliminated from major electronics products. Since

compact mini-disc player has

been available in

contains a Sn/Ag/Bi/Cu lead free solder. The product is about half the

size of a compact disc player, kind of a

portable walkman. In March

of 1999, this product will be launched in

lead free solder can be achieved

such that no problems regarding material properties, installaiton quality, and

reliability arise in actual

production and implementation is being proceeded to meet their 2001

target.

Following this product, Matsushita

will introduce lead free audio stereos, car stereos, and televisions

into

at the beginning of 1999 and

in

affected and advised to change

to lead free by

industry in the

Sony:

By 2001, all lead will be

eliminated except for high density electronics packaging.

Toshiba:

By 2000, lead will be eliminated

from mobile phones.

By 1999, lead usage reduced

to half of that in 1997. By 2001, all products will be lead-free.

In April,1998 the Japanese

started a project similar to the

Project called the NEDO project.

The project goal is to make a data base on lead-free soldering, to

select leadfree

solders, and to establish

the process for lead-free solders. The total budget is 350,000,000

yen/two years.

Project members are from major

electronics companies, device companies, solder companies, and several

universities.

Another important alloy is

the Sn/Ag/Cu system. Sn/Ag/Cu

is also on the list of the JEIDA lead free roadmap.

In addition, the European

Brite-Euram Consortia recommended Sn/Ag/Cu

as the general purpose solder. The

Sn-Ag-X lead free solders offer

superior creep resistance at room temperature and 100°C as compared to Sn-

40Pb. Results of this work

will be presented as well as factors to consider when developing and

implementing

lead free alloys such as manufacturability,

availability, and cost. One of the most promising replacement alloys

is Sn/4Ag/0.5Cu. This alloy

will be discussed in detail.

Lead free alternatives are

being considered for several reasons:

• Health Concerns

It is widely known that lead

is related to certain health risks. If lead particles are inhaled

or ingested, they

accumulate in the human body

causing damage to the blood and central nervous systems. Lead poisoning

can be

detected by blood analysis

and the limits are defined by national governments. The standard upper

value of

untainted human beings should

not exceed 130 µg/l. The upper blood lead limit of people who are

exposed to

lead at work is, according

to the

300 µg/l blood for women and

700 µg/l for men. In the

to 100 µg/l.

As a result, some industries

have already eliminated lead and have found suitable alternatives,

for example

plumbing solders, tinned cans,

lead-free gasoline for vehicles, and lead-free cut crystal glass.

The majority of

lead consumption is automobile

batteries and ammunition. The lead consumption of the electronics

industry is

relatively small and, according

to different sources, lies between 0.5 - 7%.

When choosing alternative

metals, consideration must also be given to their health risks as

well. Recent studies

in the

alternative metals:[1]

• Cd is extremely toxic and should

not be used (high risk). Many companies such as Ford Motor Company

have banned Cd-containing materials.

• Pb was also identified as highly

toxic (high risk - it is considered harmful to the reproductive system).

• Sb is very toxic and should

not be considered a major alloying element (medium risk - in Europe

this

material is considered potentially

carcinogenic).

• Ag and Cu are used in lead-free

alloys in small concentrations - in Europe these materials are seen

as low

risk.

• Sn and Zn are essential elements

in the human diet, yet may be toxic if exposures are sufficiently

high (low

risk).

• Bi is a relatively benign

metal with a history of medicinal uses (low risk).

• Greater Thermal Stress of Components

In the automotive industry,

more and more circuits are being placed in the engine compartment

in order to

reduce the quantity of cables

and, therefore, reduce cost. These under the hood conditions often

see

temperatures in excess of

150°C. A leading automobile manufacturer has even measured temperatures

as high

as 170°C on a hybrid circuit.

The high thermal stresses imposed on the solder joints at these temperatures

has

led automotive manufacturers

to research Pb-free alternatives with high

thermal fatigue resistance, because they

observed that Sn-37Pb has

poor thermal fatigue properties even at 125°C. Higher temperatures

dramatically

reduce the strength of the

solder joint during thermal cycling, due to greater plastic deformation

of the solder as

well as diffusion, recrystallization and grain growth inside the solder.

For conventional alloys such

as Sn62/Pb36/Ag2 (melting point 179°C) and Sn63/Pb37 (melting point

183°C),

there is a major concern for

the mechanical and microstructural stability

and, therefore, the reliability of the

solder joint at an operating

temperature of 150°C, because it is approaching

the melting point of the alloy.

LEAD FREE ALTERNATIVE SOLDER ALLOYS

96.5Sn/3.5Ag

221°C

This alloy exhibits adequate

wetting behavior and strength and is used

in electronics as well as plumbing.

Several sources have also

reported good thermal fatigue properties as compared to Sn/Pb.

Thermal fatigue

damage in solders is accelerated

at elevated temperatures. In the Sn/Pb system,

the relatively high solid

solubilities of Pb

in Sn and vice versa, especially at elevated

temperatures, lead to microstructural instability

due

to coarsening mechanisms.

These regions of inhomogeneous microstructural

coarsening are known to be crack

initiation sites. It is well-documented

that these types of microstructures in Sn/Pb

alloys fail by the formation of

a coarsened band in which

a fatigue crack grows. By comparison, the Sn/Ag

system, has limited solid solubility

of Ag in Sn, making it more resistant to coarsening. As a result, Sn/3.5Ag

eutectic forms a more stable, uniform

microstructure that is more

reliable.

Although the Sn/3.5Ag alloy

itself exhibits good microstructural stability,

when soldered to copper base metal,

the combination of a higher

Sn content (96.5Sn compared to 63Sn) and

higher reflow temperature environments

accelerate the diffusion rates

for copper base metal in Sn. As its corresponding

composition is reached, the

brittle Cu6Sn5 intermetallic compound is nucleated and

begins to grow. To slow the diffusion rate and thereby

decrease the growth kinetics,

alternative surface finishes such as immersion gold (Au over Ni over

Cu) may be

used. The 2 µm Ni in the immersion gold

coating serves as an effective diffusion barrier, limiting the Cu

from

diffusing into the solder

and forming the brittle Cu6Sn5 intermetallic compound. Other surface finishes

such as

immersion silver (Ag over

Cu) and immersion palladium (Pd over Cu) do not contain a Ni barrier

layer. Their

effect on the growth kinetics

of the intermetallic compound layers is

under investigation.

95.5Sn/4.0Ag/0.5Cu 217-219°C

Because the mechanical stability

of the joint is degraded when the melting point is approached, elevated

temperature cycling produces

more damage for Sn/Pb solder (m.p. 183°C) as compared to higher melting point

solders. The melting temperatures

of Sn/Ag/Cu solders make them ideal in high

operating temperatures up to

175°C. As for wetting, Sn/Ag/Cu solders do not wet Cu as well as Sn/Pb using commercial fluxes. However,

good fillet formation can

be easily achieved provided the fluxes are suitable for higher temperature

use.

Soldering in nitrogen atmosphere

also improves wettability using no-clean

fluxes. The copper dissolution test

provides a relative measurement

of the solder’s tendency to dissolve Cu from the base metal and form

the

Cu6Sn5 intermetallic compound.

99.3Sn/0.7Cu 227 °C

This alloy might be also suitable

for high temperature applications required by the automotive industry.

It is a

candidate especially for companies

looking for lead and silver free alloys. Preliminary testing conducted

on this

alloy has shown a significant

improvement in creep/fatigue data over standard Sn-Pb

alloys. However, the Sn-

Ag-X alloys perform better

in creep testing.

96.2Sn/2.5Ag/0.8Cu/0.5Sb (known as Castin) 217-220 °C

This alloy has similar mechanical

properties and reliability characteristics to the Sn/Ag/Cu alloy. However,

there is some concern regarding

the toxicity of Sb.

91.8Sn/3.4Ag/4.8Bi 200-216°C

In general, bismuth is added

to Sn/Ag/X solder alloys in order to depress

the melting point. Another benefit of

Bi addition is greater joint

strength as indicated by ring and plug testing. This particular alloy

was developed by

Sandia National Labs. Sandia’s internal studies have found no electrical failures

on surface mount devices

following 10,000 thermal cycles

using 68 I/O PLCCs, 24 I/O SOICs,

and 1206 chip capacitors on standard FR-4

PCBs. The boards were cycled

0 to 100°C at a ramp rate of 10°C/ minute. No cracks or deformation

were

observed on boards cross-sectioned

after 5000 thermal cycles. Cross-sectional data on 10,000 cycles is

being

collected. These results are

in good agreement with data collected by the

Sciences (NCMS) Lead Free

Solder Project, which reported very good thermal fatigue resistance

on OSP

printed circuit boards (Organic

Solderability Preservative that protects

copper pads and through-holes). The

NCMS High Temperature Fatigue

Resistance Project is currently evaluating this solder at temperatures

up to

160 and 175°C. In combination

with Pb from the PCB or component metallization,

a Sn/Bi/Pb ternary

compound is formed with a

melting point of only 96°C. As the trend toward eliminating lead continues,

this

alloy may become more attractive.

90Sn/2.0Ag/7.5Bi/0.5Cu (138) 198-212°C

Although the addition of Bi

to the Sn/Ag/X system imparts greater strength

and improved wetting, too much

bismuth (greater than 5%)

leads to the presence of a small DSC peak near 138°C, corresponding

to the binary

Sn/Bi eutectic at 138°C or the

ternary Sn/Ag/Bi eutectic at 136.5°C. For

this alloy with 7.5 weight percent Bi,

this corresponds to approximately

1% of the total melting. This small amount of eutectic melting has

an

uncertain effect on joint

reliability as the temperature approaches 138°C. This combined with

the

aforementioned concern of

forming a SnPbBi compound at 96°C, makes

this alloy an unlikely candidate for a

Pb-free solder.

42Sn/58Bi 138°C

The low melting point of this

alloy makes it suitable for soldering temperature-sensitive components

and

substrates. If these contain

Pb, the SnPbBi

ternary eutectic compound may form at 96°C, which in turn adversely

affects the thermal fatigue

properties. The NCMS Lead Free Solder Project recently reported the

results of

thermal cycle testing at 0/

100°C and -55/ +125°C for over 5000 cycles on OSP boards. The result

was that the

Sn/Bi outperformed the Sn/Pb at both temperature excursions. It was thought that

the closeness of 125°C to the

binary Sn/Bi

eutectic at 138°C would cause this alloy to be a poor performer. Two

possible explanations for this

unexpected result were presented.

The Sn/Bi alloy may be annealing at 125°C,

relaxing the stresses produced

during thermal cycling. A

second explanation was the alloy may be undergoing recrystallization.

Also, no filletlifting

was observed due to the eutectic

nature of the alloy.

95Sn/5Sb 232-240°C

The 95Sn-5Sb solder is a solid

solution of antimony in a tin matrix. The relatively high melting

point of this

alloy makes it suitable for

high temperature applications. The antimony imparts strength and hardness.

In

comparing the yield strengths

of several solder alloys, the strength of 95Sn/5Sb was 37.2 N/mm2 and was nearly

the same as 96.5Sn/3.5Ag (37.7

N/mm2 ).[2] The high strength of this

alloy causes the lowest energy crack path

to be at the solder/intermetallic interface in the case of thinner intermetallics. As the intermetallic

thickens, the

crack path is through the

intermetallic layer. Formation of the intermetallic

compound SbSn is possible at these

levels of Sb. This phase has a cubic structure with a high hardness.

The wetting behavior was measured on a

wetting balance in air using

a standard RMA flux. The wetting force at 2 seconds for 95Sn/5Sb on

a Cu wire is

significantly less than Sn/37Pb

and Sn/3.5Ag. In addition to marginal wetting performance, the toxicity

of Sb

has also raised concerns.

As with bismuth, antimony is also a by-product in the production of

lead.

In/Sn

52In/48Sn 118°C

The melting point of this

alloy makes it suitable to low temperature applications. With regard

to indium, it

displays good oxidation resistance,

but is susceptible to corrosion in a humid environment. It is also

a very soft

metal and has a tendency to

cold weld. In addition, the 52In/48Sn alloy displays rather poor high

temperature

fatigue behavior,

due to its low melting point. The high indium content limits the widespread

use of this alloy

due to cost and availability

constraints.

91Sn/9Zn 199°C

The presence of zinc in solder

alloys leads to oxidation and corrosion. Samples of bulk alloys that

were steam

aged for 8 hours exhibited

severe corrosion as evidenced by a purplish color.

In powder form, it reacts rapidly

with acids and alkalis and

forms a gas. Zinc-containing solder alloys have been known to react

with the flux

medium in as little as a day,

resulting in a paste that is “hard as a rock”. Thus, its compatibility

with fluxes and

its storage stability is questionable.

The reflowed solder joints do not wet as

well as other lead-free alloys.

When wave soldered, this alloy

tends to produce excessive dross. Therefore, manufacturability of

this alloy and

zinc-bearing alloys in general

is a concern.

Au/Sn

80Sn/20Au 280°C

Au/Sn

eutectic solder is a very strong, rigid solder due to the formation

of brittle intermetallic compounds.

Problems of cracked dies have

been seen using Au/Sn eutectic solders in

die attach applications. It is not known

if the cracks occur from processing

or during thermal cycling. The high cost of this alloy restricts its

use in

many applications where cost

is a factor.

DISSOLUTION KINETICS OF COPPER

In the electronics industry,

copper is commonly used as a basis material for

• conductor traces and solder

pads on the PCB

• lead frames of SO, QFP, PLCC,

and other components.

Alloys with a high tin content

and a higher melting point have a greater tendency to dissolve copper.

If a larger

quantity of copper is dissolved

from the base metal into the solder material, there is excessive formation

of the

Cu6Sn5 intermetallic phase. Solder joint reliability

can be adversely affected by the brittle nature of this

intermetallic compound, in particular the

mechanical properties of the solder joint, especially under high impact

conditions.[3]

The extent of copper dissolution

in various alloys can be evaluated by means of a simple test. A 50

gram weight

was attached to a 125 µm diameter

copper wire. A small quantity of A611 liquid flux was brushed on the

copper

wire. Then the alloy was placed

on the tip of a soldering iron (pre-heated to 280°C), and the soldering

iron was

positioned so it made contact

with the copper wire. The time it took to break the copper wire (i.e.

until the

copper dissolved in the solder)

was measured and recorded as the dissolution time.

The following alloy compositions

were tested: 60Sn/40Pb, 95Sn/4Ag/1Cu, Castin

96.2Sn/2.5Ag/0.5Sb/0.8Cu,

95.5Sn/4Ag/0.5Cu, 88Sn/3Ag/8.5Bi/0.5Cu, 88.42Sn/3.07Ag/8.51Bi,

99.3Sn/0.7Cu, and 96.5Sn/3.5Ag.

60Sn/40Pb had the slowest

rate of dissolution of the copper wire as expected due to its lower

Sn content. For

the high tin solders, the

graph shows that the addition of 0.5% copper to the solder alloy can

decrease the

dissolution rate dramatically.

In the case of the Sn/Ag/Bi alloy, the effect

of adding 0.5%Cu was to increase the

dissolution time from 1.5

minutes for Sn/Ag/Bi to 3 minutes for Sn/Ag/Bi/0.5Cu.

Figure 1. Dissolution Kinetics

of Copper in Several Solder Alloys.

THE EFFECT OF ISOTHERMAL AGING

It is important to study intermetallic growth formation because in solder joints with

coarsened Cu-Sn

intermetallics, fracture is brittle and

occurs through the intermetallic layer.

An aging study was performed on

96.5Sn/ 3.5Ag and 95.5Sn/

4Ag/ 0.5Cu solder alloys on copper substrates. The intermetallic

layer growth

characteristics of the two

alloys were compared in order to determine the effect of copper addition

to Sn-Ag

based alloys.

Two solder pastes were made,

96.5Sn/ 3.5Ag and 95.5Sn/ 4Ag/ 0.5Cu. The pastes were made with -325/

+500

mesh electronic grade (Type

3) powder. A 1000 gram batch of each paste was mixed in a small productionscale

Ross mixer at 89.5% metal

loading/ 10.5% flux by weight. Heraeus V365

no-clean/ halide-free flux was

used.

The test pieces were 2” x

2” copper coupons cut from 0.021 inch thick, commercial grade alloy

110 copper foil.

They were then pressed flat

and cleaned in acetone. The solder paste was screen printed through

an 8 mil thick,

stainless steel, laser cut

stencil on a DEK 247 printer with all printing parameters kept constant.

Therefore, the

solder volume is presumably

constant and was not considered a factor in this study. Six coupons

of each alloy

were printed. The printing

characteristics of both pastes were very good.

The test coupons were reflowed at Heraeus in a nitrogen

convection reflow oven using a standard

profile for the

pastes. The test pieces were

then placed in a Lindberg/ Blue M air convection oven held at 150°C. The samples

were aged for periods of 2,

4, 11, 20, and 41 days (984 hours). Following aging, each sample was

sectioned

across 3 joints for metallographic

examination. For each sample, the average thickness of the resulting

interfacial compound was reported.

Time (hours) Intermetallic Thickness (µm)* (Cu3Sn + Cu6Sn5)

96.5Sn/ 3.5Ag 95.5Sn/ 4Ag/ 0.5Cu

0 0.25 + 2 0.25 + 2

48 0.5 + 3.25 0.5 + 2.5

96 0.75 + 2.5 0.75 + 2.5

264 1 + 2.5 1 + 3

480 1.5 + 3 1.5 + 4.5

984 2.5 + 4 2.5 + **

*The standard deviation for

the measurements is on the order of 0.5 µm.

**A nonuniform

morphology of the Cu6Sn5 layer precluded a characteristic

thickness measurement.

It is widely known that copper

is soluble in molten Sn-Ag-X solders. The

dissolution of copper results in the

formation of å-phase Cu3Sn and ç-phase Cu6Sn5. Due to the concentration

gradient, the Cu-rich Cu3Sn phase

forms adjacent to the copper

substrate. Cu3Sn has a more

planar structure. The more Sn-rich Cu6Sn5 phase

forms adjacent to the Sn-based solder and has a scallop-edge appearance. The reason

why Cu6Sn5 has a scallopedge

appearance may be due to the

fact that Cu6Sn5 dissolves faster along the

grain boundary. Between the

Cu6Sn5 grains, there are molten solder

channels extending all the way to the Cu3Sn/Cu interface. Since the

Cu3Sn compound layer is so thin,

these channels serve as fast diffusion and dissolution paths of Cu

in the solder

to feed the interfacial reaction.[4] This interfacial layer grows

during solid-state aging as the tin and copper

diffuse to the interface and

react.

The growth kinetics of the

intermetallic compounds was found to be similar as expected

due to the similar Sn

contents and reflow temperatures of the two alloys. The microstructural features of the Sn-Ag-X

alloys are also

similar. The matrix is polygranular Sn with a grain size

in the as-solidified condition of approximately 1 µm.[5]

Five phases were identified

in the SEM micrographs: Sn, Ag3Sn, Cu6Sn5, Cu3Sn, and Cu.

Recent work indicates that

similar failure mechanisms are involved in thermal fatigue in shear

and unidirectional

creep in shear. Also, since

the temperatures during thermal fatigue represent high solder homologous

temperatures, creep deformation

is involved. Creep deformation is the time-dependent plastic flow

of a material

under constant load at elevated

temperature. As the homologous temperature (the ratio of the test

temperature to

the melting temperature on

an absolute temperature scale) increases, the ease with which plastic

flow occurs also

increases. Creep is significant

at a homologous temperature greater than 0.5. Therefore, creep deformation

occurs in solders even at

room temperature. Every high temperature excursion results in a straining

of the solder

joint as the constraining

materials expand different amounts. By understanding the mechanisms

that lead to

fatigue failures, researchers

can use the appropriate metallurgical strategy to slow down or stop

these

mechanisms and thus develop

an improved, more fatigue resistant solder alloy.[6]

The elevated operating temperature

and operative strain rates imply that creep is the major deformation

mode

during low cycle fatigue.

Also, the observation that solder joint fatigue failures and creep

failures appear the

result of similar metallurgical

mechanisms indicates that both techniques can be used to study the

fatigue failure

mechanism and relative solder

alloy fatigue resistance. As such, it becomes important to understand

how the

solder microstructure accommodates

the applied strain. For the Sn-Ag-X solders,

the strain accommodation

occurs through the tin matrix

at individual Sn-Sn grain boundaries.[5]

Creep testing was performed

on samples of the same dimension and preparation method as that used

for

standard tensile testing of

solder alloys. All creep testing was performed at International Tin

Research Institute

(ITRI). To generate the creep-rupture

data, the solder alloys were cast into dumbbell-shaped test samples

having 20 mm gauge length

and 2 mm diameter. They were cast at a temperature of 50 degrees above

the

liquidus into a heated steel mold. The mold was then water cooled.

Samples were then subjected to the

standard aging procedure of

24 hours at 125°C, in addition to at least

24 hours at room temperature for the

benefit of stabilizing the

microstructure as much as possible.

Samples were held isothermally

at both room temperature and 100°C. A weight was

hung from the sample

during the test representing

an applied stress, and the time to rupture was recorded. Samples and

test method

conformed to the British Standard

BS3500: part 3: 1969 “Method for Creep and Rupture Testing of Metals.”

Time to rupture was determined

by measuring electrical resistance across the sample; after fracture

the

resistance became infinite

and timing stopped. All samples were tested in duplicate. Data was

collected for 3

different loads (4, 8, and

16 MPa) at both temperatures. Results for

time to failure at 100, 500, and 1000 hours

were recorded. Loads were

applied which were expected to give lifetimes in the region of those

times but

extrapolation was carried

out to estimate values for the times required. The results at 25°C are shown in Figure

2. To interpret the data,

compare the times to rupture for a similar applied stress on the two

alloys. For

example, for an applied stress

of 4 MPa, Sn/40Pb failed after 265 hours,

whereas the 95.5Sn/4Ag/0.5Cu alloy

took 3000 hours for failure

to occur.

Figure 3 presents the data

collected at ITRI for several candidate lead free alloys compared

to Sn/40Pb. The

95.5Sn/4Ag/0.5Cu alloy performs

the best at room temperature compared to Sn/3.5Ag eutectic, Sn/0.7Cu

eutectic, and Sn/40Pb. As

expected, the Sn/Ag/Cu and Sn/Ag

alloys behave similarly due to their similar

microstructural development. The graphic

representation of the Sn/Cu data greatly

differs from that of the other

three, perhaps indicative

of a different failure mechanism. The results of creep testing at

100°C are presented in

Figure 4. At 100°C, the Sn/Ag and Sn/Ag/Cu curves appear switched from the 25°C results with the best

performer now being the Sn/Ag eutectic alloy. Figure 5 shows the creep-rupture data

for the Heraeus

Sn/4Ag/0.5Cu alloy tested

at both room temperature and 100°C. As expected, higher temperatures

allow

materials to creep at a faster

rate, thereby reducing the time to failure.

Figure 2. Creep-Rupture Data

for Heraeus Sn-4Ag-0.5Cu and Sn-40Pb at

25°C.

Figure 3. Creep-Rupture Data

for Several Candidate Lead Free Alloys Compared to Sn-40Pb at 25°C.

Figure 4. Creep-Rupture Data

for Several Candidate Lead Free Alloys Compared to Sn-40Pb at 100°C.

Figure 5. Creep-Rupture Data

for the Heraeus Sn/4Ag/0.5Cu Alloy Tested

at 25°C and 100°C.

This first lesson appears

too easy and is often overlooked. When testing Bi-containing lead

free alloys, many

companies have had to scrap

many hours worth of otherwise valuable data because they used the

standard Sn/Pb

component finish or PWB board

metallization. As reported earlier, in combination with Pb from the PWB or

component metallization, a

Sn/Bi/Pb ternary compound is formed with a melting point of

only 96°C. These

joints would not be able to

undergo thermal cycling and are technically unsalvageable.

This second valuable lesson

is not so obvious and was discovered by the NCMS High Temperature

Fatigue

Resistant Solder Project Team.

Components used for the PWB and hybrid assemblies for the

Thermomechanical Fatigue Test build had leads

or castellations, in the case of the LCCCs, pretinned with pure

tin. The large volume of Sn on the leads and castellations

resulted in a contamination of the final solder joints.

The problem was initially

identified in the case of the high lead alloys because they melted

at the eutectic

temperature of 183°C and had the eutectic Sn/Pb

morphology. The problem was less severe in the Sn-based

lead free alloys but still

a major problem. With the LCC 44 component, a 50% dilution of the

alloys was

reported. The Sn contamination for the PLCCs was

far less as expected, since the “tinning” volume is much

less, with only a 15 -20 micron

thick coating on the leads. A 10% dilution was reported for the PLCC

components. The selected alloys

were far enough from their targeted compositions that the NCMS Team

chose

to repeat the entire assembly.

In the future work of the project, components will not be supplied

with pure tin or

tin-lead solder. The preferred

alternative is to prealloy the components

with the test alloys to avoid

contamination.

Recent work with candidate

lead free alloys indicate a significant improvement in reliability

over Sn/Pb.

Figures 2-4 clearly demonstrate

a superior creep resistance over Sn/Pb for

all lead free alloys tested including

Sn/Ag eutectic, Sn/Cu eutectic, and Sn/4Ag/0.5Cu at both room temperature

and 100°C. Although the Sn/Cu

eutectic outperformed Sn/40Pb,

it did not perform as well as the Sn-Ag-X

alloys.

An aging study of both the

95.5Sn/4Ag/0.5Cu and 96.5Sn/3.5Ag solder alloys was performed in order

to

evaluate the growth kinetics

of the intermetallic layers following extended

heat treatment. An understanding of

the microstructural

evolution that occurs at the solder/copper interface at elevated temperatures

is helpful to

understand the failure mechanisms

that dominate at elevated temperatures. Creep occurs when materials

under

constant stress, below the

tensile stress, slowly deform and finally fracture. The creep rate

is dependent on alloy

composition and microstructure

and is strongly temperature dependent. Because Sn/Ag and Sn/Ag/Cu have

similar microstructures, they

behave similarly during isothermal aging and creep testing.

The author is grateful to

acknowledge the support of the International Tin Research Institute

for mechanical

testing of the alloys. The

metallographic preparation and scanning electron microscopy of the

samples used to

study aging was performed

by F.W. Gayle and L. Smith at the National Institute of Standards

and Technology

and is greatly appreciated.

Also, thanks to Dr. M.R. Notis of

1.

2. P.T. Vianco, K.L. Erickson,

and P.L. Hopkins, “

Copper and High Temperature,

Tin-Rich Solders-Part I: Experimental Analysis,” Sandia National Labs

(Contract Number DE-AC04-94AL85000),

1994.

3. G. Humpston and D.M. Jacobson,

Principles of

Soldering and Brazing, ASM International, 1993.

4. H.K. Kim and K.N. Tu, “Kinetic

Analysis of the Soldering Reaction Between Eutectic SnPb Alloy and Cu

Accompanied by Ripening,”

Physical Review B, Vol. 53, No. 23,

5. D.R. Frear, “The Mechanical

Behavior of Interconnect Materials for Electronic

Packaging,” J.Metals, (May

1996), pp. 49-53.

6. J.W. Morris, Jr. and D.

Tribula, “Creep in Shear of Experimental Solder Joints,” Journal of Electronic

Packaging, June 1990, Vol. 112, pp. 87-93.

Previously published

in German in

Productronic,

11/97.

©Productronic,

1997

Anton

Zoran Miric

W.C.

Heraeus GmbH,

Angela

Grusd

Heraeus

Cermalloy Division, West

[ 19

]

In recent years, efforts

to develop alternatives to leadbased solders

have increased dramatically. These efforts began as a response to

potential legislation and regulations restricting lead usage in the

electronics industry. Lead is extremely toxic when inhaled or ingested.

As researchers began to focus on Pb-free

solders, they recognized their value in high temperature applications

(e.g. automotive manufacturing) where Sn/Pb solders do not meet the requirements.

There are many factors

to consider when developing lead-free alloys: manufacturability, availability,

reliability, cost and environmental safety. Of these, the most challenging

and time consuming is the reliability of alternative solders. The

lead-free alloys available cannot be used as a drop-in replacement

for the SnPb or SnPbAg.

The introduction of lead-free solder alloys may mean having to use

alternative component and PCB metallizations,

PCB materials, solder fluxes, etc.

Lead is

used in the electronics industry as a part of the solder material

alloy. For some time, now, alternative materials have been called

for, for several reasons.

Greater thermal stress

of components

In the

automotive industry, more and more circuits are being

• greater

plastic deformation of the solder;

• recrystallisation and grain growth inside the solder.

At such

high temperatures, the mechanical properties of the

service

temperature is c. 97 per cent of the melting temperature

Minimisation of health

risks

The use

of lead alloys is related to certain health risks, e.g.

If chronically

exposed to lead, an accumulation of lead in

In the

manufacturing environment, lead constitutes only a

A greater

danger lies in the contamination of ground

Several

proposals have been made to limit, tax or ban the

Nevertheless,

one has to remember that the major part of

The lead

consumption of the electronics industry is

When choosing

alternative metals, consideration must

• Cd is extremely toxic and should not be used (high risk).

• Pb was also identified as highly toxic (high risk – in

• Sb is very toxic and should not be considered a major

• Ag and

Cu are used in lead-free alloys in small concentrations

• Sn and Zn are essential elements in the human diet, yet

• Bi is

a relatively benign metal with a history of medicinal

Use of temperature-sensitive

components and

Many industries

strive to reduce costs. Components and

This is

especially apparent with consumer electronics, as

2. Alternative materials and solder

alloys

Some alternative

basis metals and their alloys are shown in

Sn/Ag: 96.5Sn/3.5Ag; 221°C

This alloy

exhibits adequate wetting behaviour and strength

Several

sources have also reported good thermal fatigue

These regions

of inhomogeneous microstructural coarsening

Although

the Sn-3.5Ag alloy itself exhibits good

Technology

|

|

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||

|

|

10/1 [1998]

19–25

Anton Zoran Miric and

Anton Zoran Miric and

The Ni

in the immersion gold coating serves as a diffusion

surface

finishes such as immersion silver (Ag over Cu) and

Sn/Ag/Cu

1 95.5Sn/4.0Ag/0.5Cu; 216-219°C

2 95.5Sn/3.8Ag/0.7Cu; 217-219°C

3 95.0Sn/4.0Ag/1.0Cu; 216-219°C

4 93.6Sn/4.7Ag/1.7Cu;

216-218°C

Because

the mechanical stability of the joint is degraded

point 183°C)

as compared to higher melting point solders.

The melting

temperatures of Sn-Ag-Cu solders make them

using commercial

fluxes. However, improved wetting is

Sn/Cu:

99.3Sn/0.7Cu; 227°C

This alloy

might be also suitable for high temperature

Sn/Ag/Cu/Sb: 96.7Sn/2Ag/0.8Cu/0.5Sb

(known as Castin-Alloy); 217-220°C

This alloy

has similar properties to the Sn/Ag/Cu alloy.

Sn/Ag/Bi: 91.8Sn/3.4Ag/4.8Bi;

200-216°C

In general,

bismuth is added to Sn-Ag-X solder alloys

in

In combination

with Pb from the PCB or component

Sn/Ag/Bi/Cu: 90Sn/2.0Ag/7.5Bi/0.5Cu;

(138) 198-212°C

Although

the addition of Bi to the Sn-Ag-X system

imparts

Sn/Bi:

42Sn/58Bi; 138°C

The low

melting point of this alloy makes it suitable for

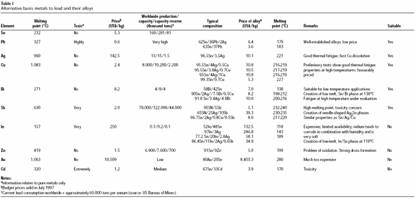

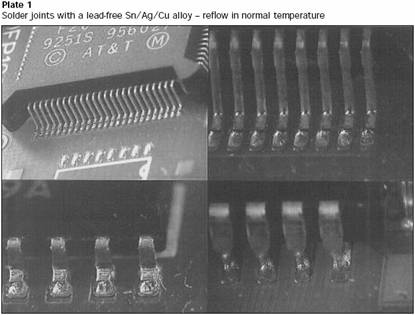

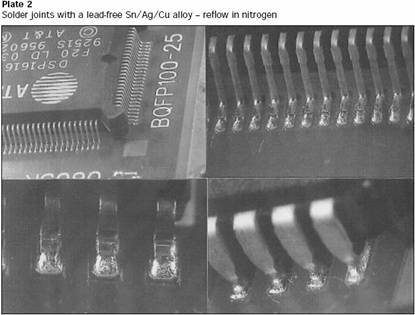

Solder joints with a

lead-free Sn/Ag/Cu alloy – reflow